SaniForce Electric Diaphragm Pump

• Only electric positive displacement diaphragm pump on the market that will stall under pressure

• No hydraulic backing – reduces threat of contamination

• Up to 5x more efficient than AODD

• Reduces pulsation without the addition of pulsation dampeners

• Diaphragm pump design - runs dry, self-primes, seal-less design

• No exhaust, low noise

• Electric units for large particle transfer

• Only electric positive displacement diaphragm pump on the market that will stall under pressure

• No hydraulic backing – reduces threat of contamination

• Up to 5x more efficient than AODD

• Reduces pulsation without the addition of pulsation dampeners

• Diaphragm pump design - runs dry, self-primes, seal-less design

• No exhaust, low noise

• Electric units for large particle transfer

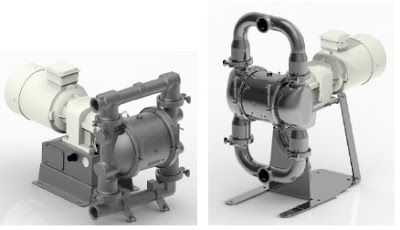

AC Washdown Motor Pumps

BLDC Washdown Motor Pumps

Cart Mount Units

Product Family - SaniForce 2.0

Food Grade (FG)

• Food grade wetted section

• 125 Ra finish

• Ideal for beverage, sauce, and food ingredient transfer

• No rotary seals

• High sanitary fluid section

• 32 Ra finish

• Ideal for personal care, cosmetic, and food ingredient transfer

• No rotary seals

• Stalls under pressure

High Sanitary (HS) Flapper Check

• High sanitary fluid section

• Pass up to 3-78” solids

• Ideal for personal care, food ingredients, and meat and poultry

• No rotary seals

• Stalls under pressure

• Pharma grade fluid section

• 20 Ra surface finish

• Electropolished wetted parts

• Ideal for bio-pharm, personal care, cosmetics

• No rotary seals

• Stalls under pressure

SaniForce EODD Feature Overview

Two Types of Motor

• AC motor washdown

• Operate on 220 or 480V

• Brushless DC motor

Two Gearbox Standards

• NEMA motor gearbox

• IEC motor gearbox

VFD & Air-charge Compressor Options

Four Product Offerings

• AC motor package

• Bare pump w/ IEC or NEMA gearbox

• DC motor package with smart control

• Cart-mounted DC motor package w/ smart control and compressor

Technical Specifications

• SaniForce e-series pumps are ideal for applications that require low pulsation and a smooth flow. The air charged cam drive allows the elimination or reduction of pulsation WITHOUT pulsation dampeners or surge tanks.

• To reduce outlet pulsation, start by setting the air pressure equal to the desired outlet fluid pressure.

Competitive Technologies